What Is The Process of Dead Burnt Magnesia?

About dead-burned magnesia

Dead-burned magnesia also known as DBM, is an important refractory material with a variety of industrial uses. It is known for its ability to withstand harsh chemicals and high temperatures. Understanding how dead-burned magnesium oxide is produced is critical to understanding its importance in various industries including cement, ceramics and steel.

The process of making dead-burned magnesia begins with the careful selection of its main ingredient: magnesite ore. Magnesite is a natural mineral consisting primarily of magnesium carbonate (MgCO3). To manufacture high-quality DBM, it is best to use pure magnesite as impurities can affect the properties of the final product.

The process of dead-burned magnesia

After magnesite is extracted from the mine, it goes through a crushing and screening process. First, crush the magnesite into small pieces to make subsequent steps easier. Chip size should comply with the specific product requirements for dead burnt magnesium oxide. The calcination step is the concentrated stage in the production of dead-burnt magnesium oxide. Calcining involves subjecting crushed magnesite to temperatures in excess of 1,500 degrees Celsius (2,732 degrees Fahrenheit), which is where the term “recalcined” comes from. This process removes all carbon dioxide (CO2) and water (H2O) from the magnesite, leaving only pure magnesium oxide (MgO). The temperature is precisely controlled to ensure complete conversion without over-burning.

When calcined, magnesite particles expand significantly due to the release of CO2 and H2O. This expansion is essential to create a porous, sponge-like structure in dead-burned magnesium oxide, thereby enhancing its fire-resistant properties. The material obtained after calcination is called dead-burned magnesia. To prevent any unexpected changes, the dead-burnt magnesium oxide is quickly cooled to room temperature after calcination. After cooling, the material is crushed and adjusted to the required particle size based on its intended application. The performance of a refractory lining can be affected by particle size distribution, so this is a key factor to consider.

Quality control is an important aspect of the process.

Quality control is an essential component in the production of dead-burned magnesia. We carefully test and analyze our products to ensure they meet industry standards. Important factors we evaluate include chemical composition, particle size, bulk density, and impurity content. Our thorough quality control ensures that dead-burned magnesia is suitable for a variety of high-temperature applications.

Additional reading:Understanding the Composition of Tungsten Carbide Rod

What Are Wear Plates Used For?

Hastelloy Clad Plate: The Perfect Fusion of Strength and Corrosion Resistance

Are There Different Types of Aluminum Coils?

What are the difference between ball bearings and roller bearings?

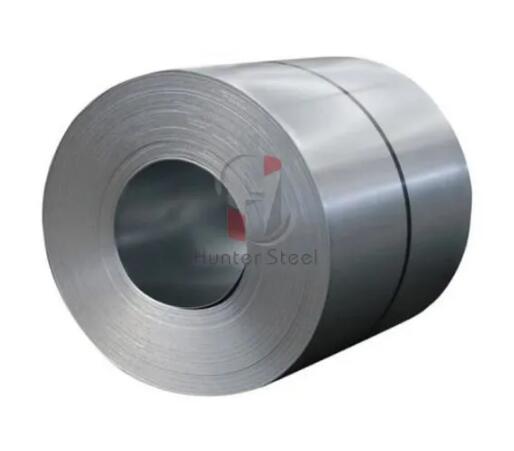

What are the advantages of using galvanized steel coils?

What To Consider When Choosing Business Trash Cans

Application of dead-burned magnesia

Dead-burned magnesia is used in many industrial applications due to its excellent ability to withstand high temperatures. The cement industry also uses dead-burned magnesium oxide to improve its fire-resistant properties. The cement industry also uses dead-burned magnesium oxide to improve its fire-resistant properties. The cement industry also uses dead-burned magnesia due to its refractory properties. In the steel industry, dead-burned magnesium oxide is an important component of the refractory linings of furnaces, converters, and ladles due to its high melting point. It is used in the steel and cement industries due to its fire-resistant properties. In the steel industry, dead-burned magnesium oxide is an important component of the refractory linings of furnaces, converters, and ladles due to its high melting point. In the steel industry, dead-burned magnesia is an important component of the refractory linings of furnaces, converters, and ladles due to its high melting point. This makes it resistant to slag and metal corrosion, which is necessary for the steelmaking process. In cement furnaces, dead-burned magnesia is used as a durable lining material to withstand high temperatures and corrosive conditions. Dead-burned magnesium oxide is also used in the ceramic industry to make kiln furniture, crucibles, and other high-temperature-resistant components. Additionally, it is used in the glass manufacturing industry to build regenerators that help save heat during the glass melting process and increase energy efficiency.

Environmental Applications: DBM is used in waste incinerators and hazardous waste treatment facilities where resistance to high temperatures and chemical attack is critical.

In summary

Dead burnt magnesia is produced by calcining magnesite ore and is an essential refractory material with a wide range of industrial uses. Its ability to withstand extreme temperatures and harsh chemical environments makes it indispensable in areas such as steel, cement, ceramics, and glass. Understanding how it is made is critical to understanding its use in many high-temperature applications. It is reliable and powerful, making it ideal for these applications.

Sintered Porous Metal Stainless Steel Discs: Versatile and Reliable

The Essential Guide to Drill Pipe: What You Need to Know?

The Journey from Bauxite to Brilliance: Unveiling the Production of Aluminum Coils

Somthing you need to know about safety wire?

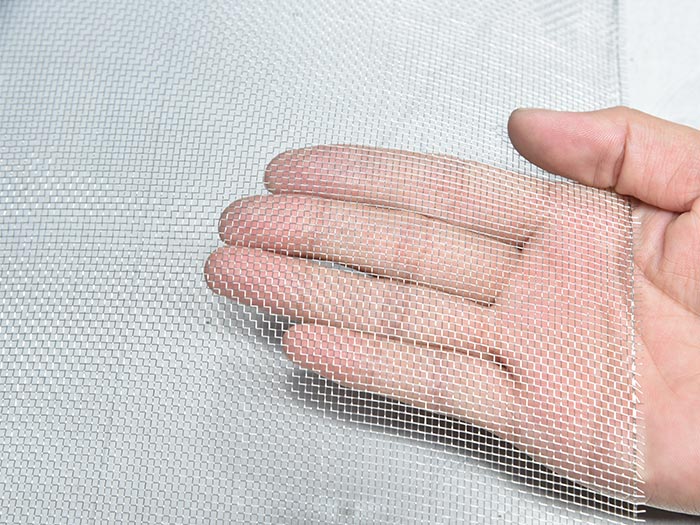

Double Wire Mesh Fence vs Chain Link Fence: Which One Reigns Supreme?

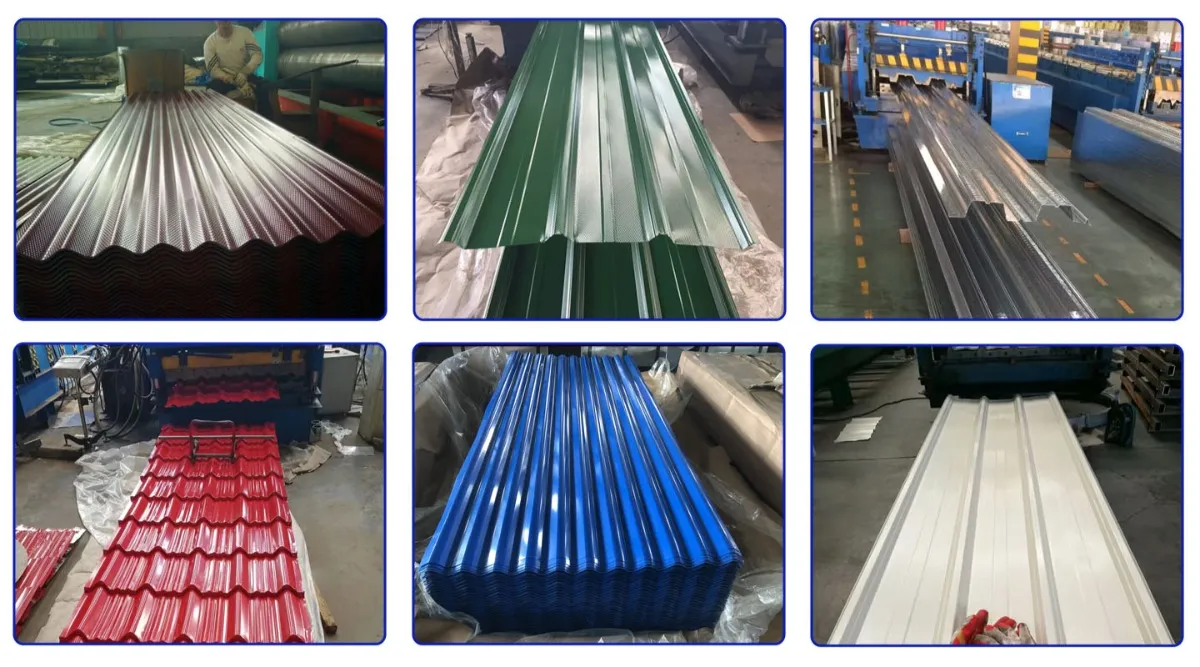

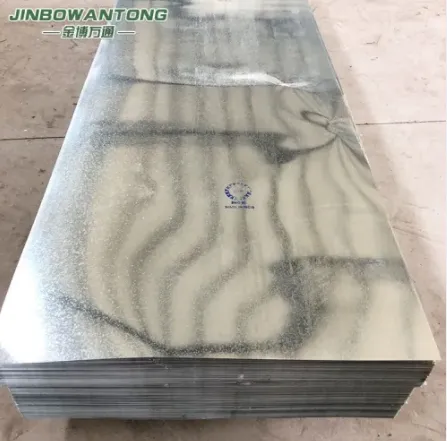

Frequently Asked Questions about Galvanized Corrugated Steel Plate

Which black color is the best?