What Does Protective Film Do?

Meta description: Discover the significance of protective films in various industries, including automotive and electronics, and learn how to choose the right protective film for your needs.

You’ve just purchased your new car, eagerly preparing to take it for a spin, when you notice a long scratch along the side. The reason? A lack of protective film.

Protective film has long been the unseen shield that keeps your new vehicle looking flawless from the factory to the dealership.

For years, NB Technology has been at the forefront of innovation, creating custom protective films that safeguard not just vehicles, but a wide array of products and surfaces.

When you explore the benefits of protective film in the industry, you’ll understand how it protects cars, devices, and surfaces from everyday wear and tear.

What is Protective Film?

Protective film is a material designed to protect surfaces from damage, such as scratches, abrasions, and other impacts. Initially developed for military use, it now serves many civilian applications, offering critical protection across various industries.

What Constitutes Protective Film?

The composition of protective films varies based on their application, with materials often tailored to the specific needs of different industries:

Low-density polyethylene: Light, flexible, and elastic.

Polyvinyl chloride (PVC): Ideal for protecting metal surfaces, known for its sleek finish and elasticity.

Polypropylene: Durable even at high temperatures, suitable for various applications.

Polyolefin: Often used with glass or painted metal, with specialized variants for packaging.

Co-extruded, low-density polyethylene: Layers provide enhanced protection.

Paper: Used for very low-impact protection.

Understanding these materials enables manufacturers like NB Technology to create protective films tailored to industry-specific needs.

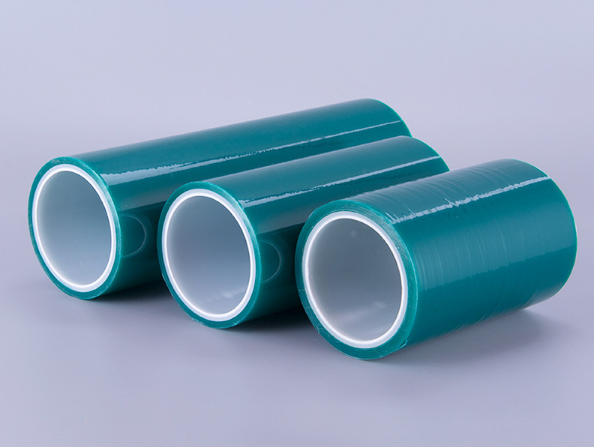

Types of Protective Film

Protective films come in various forms, each designed for specific uses based on factors such as thickness, material, and adhesive strength. The two main types include:

1. Surface Protective Film

A quality surface protective film shields vulnerable surfaces like glass, stone, brick, and metal. Applied during manufacturing and transport, it prevents damage but can be tricky to install without bubbling, often requiring professional application.

2. Protection Film for Painted Surfaces

Paint protection films provide superior impact resistance and self-healing properties. Composed of elastomeric polymers, they protect against environmental damage and are nearly invisible, making them a popular choice for cars, electronics, and aerospace applications.

Benefits of Using Protective Film

The applications of protective film are vast, especially in industries like aerospace, automotive, electronics, and the medical sector. Key benefits include:

Protection against scratches and abrasions.

Resistance to humidity, temperature fluctuations, and UV rays.

Chemical resistance for easy cleaning and maintenance.

Electronics

From smartphones to televisions, protective film is crucial for safeguarding screens and delicate components during manufacturing and shipment.

Industrial Applications

In industrial settings, protective films are often customized for specific equipment or products. They prevent damage during transit, particularly for newly manufactured items.

Automotive

Cars benefit significantly from protective films, applied to areas such as bumpers and doors, offering protection without compromising aesthetics.

Medical Equipment

Medical devices require regular maintenance to prevent corrosion and damage. Adding a protective layer helps extend the lifespan of these costly machines.

How to Choose the Right Protective Film

Selecting the ideal protective film for your needs involves considering several factors:

Longevity: Choose a high-quality, durable film to avoid frequent replacements.

Warranty: Opt for films with a solid warranty, like Pregis PPF, which offers up to 10 years of coverage.

Quality: Ensure the film meets basic requirements, such as resistance to scratches, UV rays, and abrasion. Quality doesn’t always have to mean expensive.

Application: Installing protective film can be tricky. Hiring a professional ensures a smooth, bubble-free application.

If you’re considering protective film for your product, NB Technology offers highly customized solutions to fit your specific needs.