What is LVL core?

LVL stands for Laminated Veneer Lumber, and an LVL core refers to the central structural component of a material or product made from laminated veneer lumber. LVL is a type of engineered wood product that is commonly used in construction for its strength and versatility.

LVL Core Characteristics:

Composition:

The LVL core is typically composed of thin layers of wood veneers. These veneers are stacked and glued together with their wood grains aligned parallel to each other.

Adhesive Bonding:

The layers of veneer in the LVL core are bonded together with a strong adhesive, often a type of resin. This bonding process contributes to the material's structural integrity and enhances its load-bearing capabilities.

Grain Orientation:

The orientation of the wood grain in each layer of the core is a key aspect. By aligning the grain direction, LVL can achieve higher strength and stiffness compared to traditional lumber.

Uniformity:

LVL cores are manufactured to be highly uniform in terms of strength and dimension. This consistency allows for predictable and reliable performance in various applications.

High Strength:

LVL is known for its high strength-to-weight ratio. The engineered composition of the core provides superior strength, making it suitable for applications where traditional lumber may be less effective.

Dimensional Stability:

Additional reading:Benefits of Using Anaerobic Digester Tanks

What Is the Tolerance for Slipform Construction?

Types of Geomembrane

How do you join Aluminium corners?

300 Ton Cooling Tower vs 400 Ton Cooling Tower: A Comprehensive Comparison

Advantages of Ceramic Cylinder Liner

Exploring the World of Flat Pack Container Houses

LVL exhibits good dimensional stability, meaning it is less prone to warping, twisting, or shrinking compared to some solid wood products. This stability is advantageous in construction and other structural applications.

Applications of LVL Core:

Structural Beams and Headers:

LVL cores are often used to manufacture beams and headers in construction. These components provide structural support in buildings, bridges, and other architectural projects.

Lintels:

Lintels, which are horizontal supports above openings like windows and doors, can be constructed using LVL cores for their strength and durability.

Columns:

LVL cores are employed in the production of structural columns, offering a reliable and strong material for vertical support in buildings.

Floor and Roof Joists:

LVL cores are utilized in the creation of floor and roof joists, contributing to the stability and load-bearing capacity of these structural elements.

Plywood and LVL Panels:

LVL cores are also used in the manufacturing of plywood and LVL panels, which find application in various construction and woodworking projects.

The use of LVL door cores in construction and woodworking provides an engineered wood solution that combines strength, dimensional stability, and versatility, making it a popular choice in modern building practices.

Analysis! The most comprehensive steel structure knowledge...

Simple understanding: The difference between single-story and multi-story steel structure factory building design

Detailed explanation! Steel structure engineering you want to know

Unleash Your Creativity with Vitreous Glass Mosaics: A World of Color and Artistry

5 Easy Ways to Repair Pool Tiles

Are Expandable Container Houses Eco-Friendly and Sustainable?

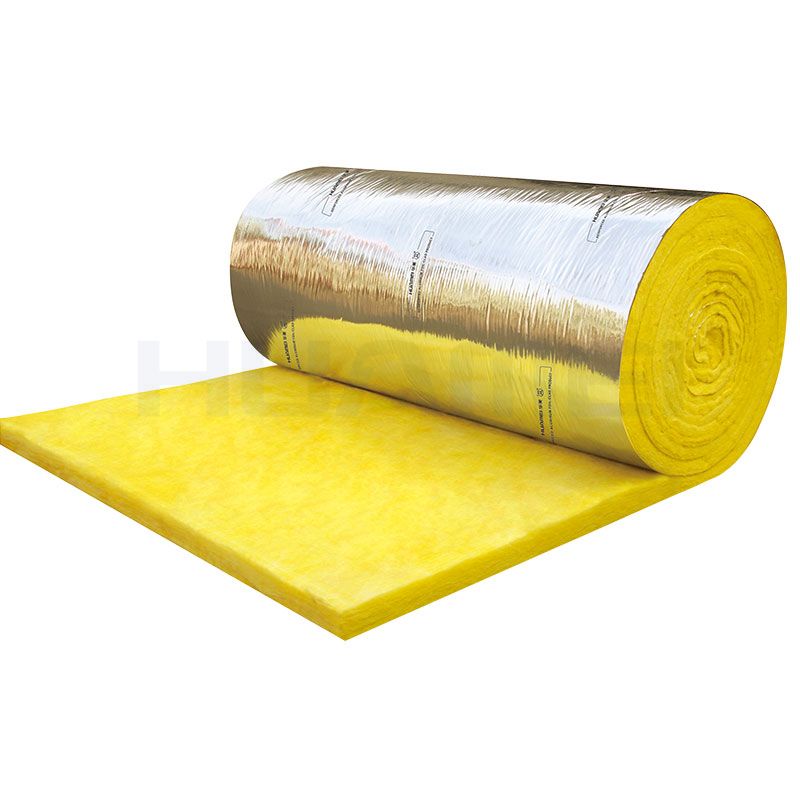

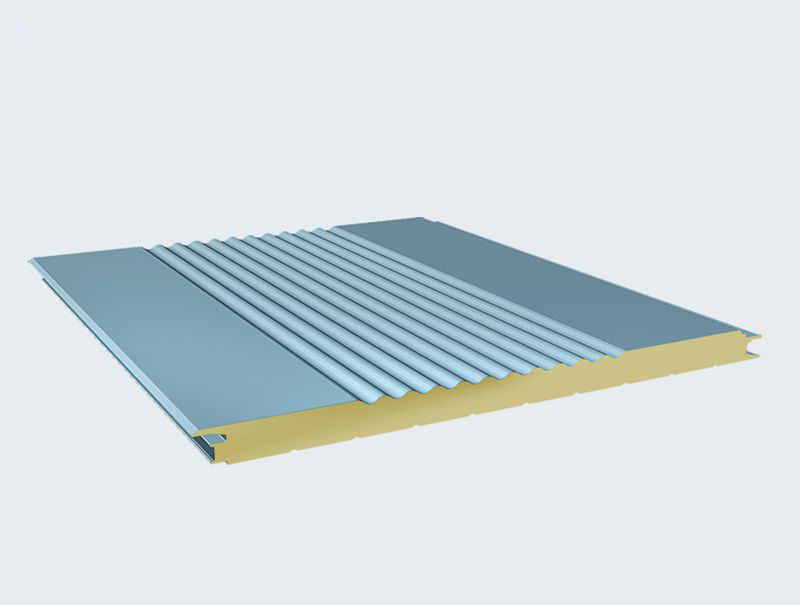

Cooling Innovation: Glass Wool Air Conditioning Panels for Efficient Climate Control

- Previous: None

- Next: None