Smart Guide: Quarry Screen Mesh Scalping Prices Explained!

When it comes to quarry operations, understanding scalping and associated costs is essential for optimizing your workflow and budget. This Smart Guide explains everything you need to know about quarry screen mesh scalping prices, backed by reliable statistics and data.

What is Quarry Screen Mesh Scalping?

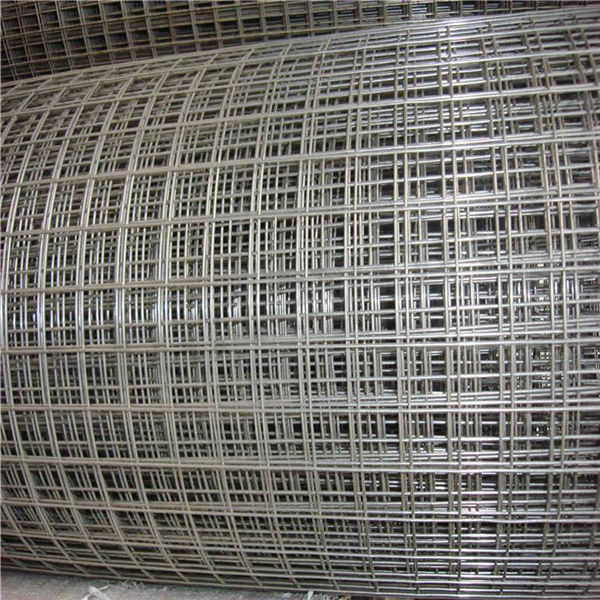

Quarry screen mesh scalping is the initial step in the process of separating materials. It involves the removal of unwanted larger rocks from the product through a mesh screen. This process is crucial for enhancing product quality and ensuring that the final output meets industry standards.

Types of Quarry Screen Mesh

There are various types of screen meshes used in quarry operations, each suited for different applications. These include:

- Woven Wire Mesh: Known for its versatility and strength, typically made from high-carbon steel.

- Punched Plate: Used for heavier applications and characterized by its long lifespan and durability.

- Polyurethane Screens: Flexible and resistant to wear, suitable for finer materials.

Factors Influencing Scalping Prices

Several key factors affect the pricing of quarry screen mesh:

1. Material Type

The type of material used in the manufacture of the screen mesh has a significant impact on pricing. For instance, high-carbon steel meshes are generally more expensive than their polyurethane counterparts. According to Industry Web, woven wire meshes can range from $0.50 to $2.00 per square foot.

2. Mesh Size

The size of the openings in the mesh also dictates the price. Finer meshes are often more costly due to the manufacturing processes involved. Statistics from the Mesh Market Data indicate that mesh sizes below 1/4 inch can cost as much as $3.50 per square foot.

3. Thickness and Coating

Thicker and coated meshes, which provide additional durability and resistance, typically incur higher costs. As per a report from Materials Pricing, prices for heavy-duty coated screens can exceed $4.00 per square foot.

Market Trends and Economic Data

Market trends indicate that the quarry screening materials market is expected to grow at a CAGR of 5.1% between 2022 and 2027 (Market Research Org). This growth is driven by increasing construction activities, which demand efficient material separation processes.

Additional reading:**Where to Find the Best Quarry Screen Mesh Prices?**

Average Costs and Pricing Models

How to Choose the Best Security Fence Price?

Is Welded Razor Wire Mesh Worth the Investment for Security?

Why Choose 3D Curved Wire Mesh Fence for Security?

How to Determine Razor Wire Mesh Cost?

How Do Decorative Garden Fences Enhance Your Landscape?

4 Tips to Select the Perfect Coffee Blend in Honduras

On average, quarry screen mesh scalping prices can be broken down as follows:

- Low-End Price: $0.50 to $1.00 per square foot for standard woven wire.

- Mid-Range Price: $1.00 to $2.50 per square foot for typical punched plates.

- High-End Price: $2.50 to $4.00+ per square foot for specialized coatings or custom sizes.

Cost-Saving Strategies

To manage expenses effectively, consider the following strategies:

1. Bulk Purchasing

Buying in bulk can substantially reduce per-unit costs. Suppliers often provide discounts for larger orders.

2. Selecting the Right Mesh for Your Needs

Evaluate the specific requirements of your project to determine the most cost-effective mesh type. Investing in the right mesh can save costs in the long run by reducing frequent replacements.

3. Regular Maintenance

Implementing regular maintenance can extend the lifespan of your mesh screens, minimizing the need for replacements.

Conclusion

Understanding quarry screen mesh scalping prices is crucial for optimizing budgets and maintaining efficiency in quarry operations. By considering the factors that influence costs and employing effective strategies, businesses can maximize their returns while ensuring product quality. For more insights, check the sources used in this guide and stay informed on the latest market trends.

Contact us to discuss your requirements of quarry screen mesh for scalping price, round hole perforated metal mesh, Quarry Mesh rolls wholesale. Our experienced sales team can help you identify the options that best suit your needs.

Additional reading:How Effective is Cangchen High Silica Filter?

How to Choose Cangchen High Silica Fiberglass Fabric Filter for Industrial Applications?

How to Choose the Best Bronze Mesh Screen for Home Projects

Why Choose Bronze Mesh Screens for Your Home: Top Benefits

How to Choose Intricate Decorative Wire Mesh?

Top Trends in Intricate Decorative Wire Mesh 2024

How is Welded Mesh Measured and What are the Dimensions of Welded Mesh?