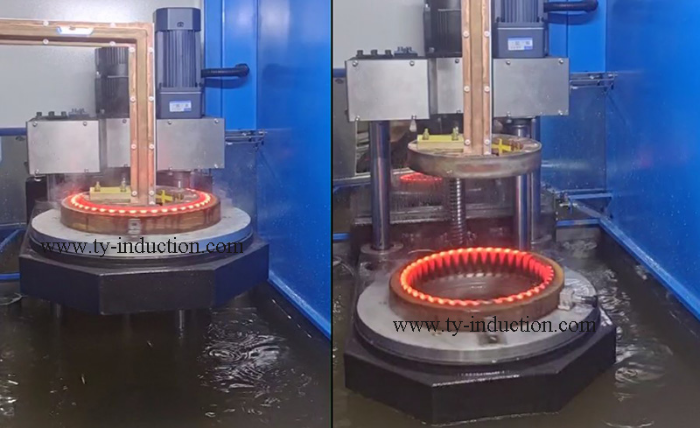

Gears Induction Hardening Equipment Accepted by African Customer

We are excited to announce that our Gears Induction Hardening Equipment has been accepted by an esteemed African customer.

At the beginning of the new year, a group of an African customer came to our factory to inspect and accept the Gears Induction Hardening Equipment they ordered.

First, they had a factory tour by guiding of the general manager. Customers highly appreciate the standardized management of our factory.

After testing and evaluation, our Gears Induction Hardening System meets all the requirements and specifications set by our customers. Customers were particularly impressed by the equipment's precision and efficiency in hardening gears, which are key components in the manufacturing process.

What metal is most similar to aluminum?

304 304L Dual Certified Stainless Steel

When were steel pipes invented?

22 Cost-Saving Ideas For Companies

Grade Guide: AISI 4140 Steel

Introduction to stainless steels

Steel: Definition, Composition, Types, Properties, and Applications

Our Gears Induction Quenching Equipment uses CNC system and Siemens PLC control to achieve high precision and consistency during the quenching process. It provides excellent heating control and uniform quenching, resulting in increased gear hardness and durability. The hardening process carries out by working with an IGBT technology Induction Power Converter, an Induction Coil, a CNC quenching machine and two water cooling systems. The internal ring gear in pictures is 304mm in diameter and 40mm in height.

African customers' recognition of our equipment increases our confidence in providing customers with higher quality, reliable solutions. We are grateful for their trust and look forward to building further partnerships in the future.

This achievement also validates our expertise in developing and manufacturing specialized induction hardening equipment for various industries. We continually strive to improve our products and incorporate new technological advancements to meet the growing needs of our customers around the world.

We are grateful to the team of engineers and technicians who worked hard to design this device.

As we continue to expand our presence in Africa and other regions, we remain committed to providing excellent customer service and delivering best-in-class products to meet our customers' specific needs.

Additional reading:The Ultimate Guide to Choosing Industrial Metal

Role of nickel in stainless steel

What is the difference between a sludge pump and a slurry pump?

Difference Between Quartz Powder and Silica Fume

How Much Weight Can a Heavy Duty Zip Tie Hold?

The Strength and Versatility of PC (Prestressed Concrete) Wire

What Is Tantalum Powder?

- Previous: None

- Next: None