Does Mesh Stop Concrete Cracking?

https://www.xghwsteel.com/products/concrete-slab-mesh.html

Concrete is a widely used construction material known for its strength and durability. However, one common issue that plagues concrete structures is cracking. Cracking in concrete can lead to aesthetic problems and structural concerns. One method to mitigate cracking is by using mesh reinforcement. But does mesh really stop concrete from cracking? In this article, we will delve into the role of mesh in preventing concrete cracks, the types of mesh used, and how effective it is in enhancing the durability of concrete structures.

Understanding Concrete Cracking

Why Does Concrete Crack?

Concrete cracking can occur due to various reasons. Shrinkage, temperature changes, load stress, and improper curing are some of the primary factors that cause concrete to crack.

Shrinkage: As concrete dries, it tends to shrink. This shrinkage can cause tensile stress, leading to cracks, especially if the concrete is restrained.

Temperature Changes: Concrete expands and contracts with temperature fluctuations. Extreme temperature changes can create significant stress within the concrete, resulting in cracks.

Load Stress: Heavy loads or impact stress can exceed the tensile strength of concrete, causing it to crack.

Improper Curing: Inadequate curing can lead to rapid drying and shrinkage, increasing the likelihood of cracking.

Types of Concrete Cracks

Concrete cracks can be classified into various types based on their causes:

Plastic Shrinkage Cracks: These occur when the concrete is still in its plastic state and typically appear on the surface.

Drying Shrinkage Cracks: These develop as the concrete hardens and loses moisture.

Thermal Cracks: Caused by temperature variations, these cracks can appear during or after the curing process.

Settlement Cracks: These occur when the ground beneath the concrete settles unevenly.

Structural Cracks: Resulting from load stress, these cracks can compromise the integrity of the structure.

Role of Mesh in Concrete Reinforcement

What is Mesh Reinforcement?

Mesh reinforcement involves embedding a network of steel or synthetic fibers into the concrete to enhance its tensile strength and crack resistance. The mesh acts as a tension-resistant layer, helping to distribute the load and stress more evenly across the concrete structure.

Types of Mesh Used in Concrete

There are several types of mesh used in concrete reinforcement:

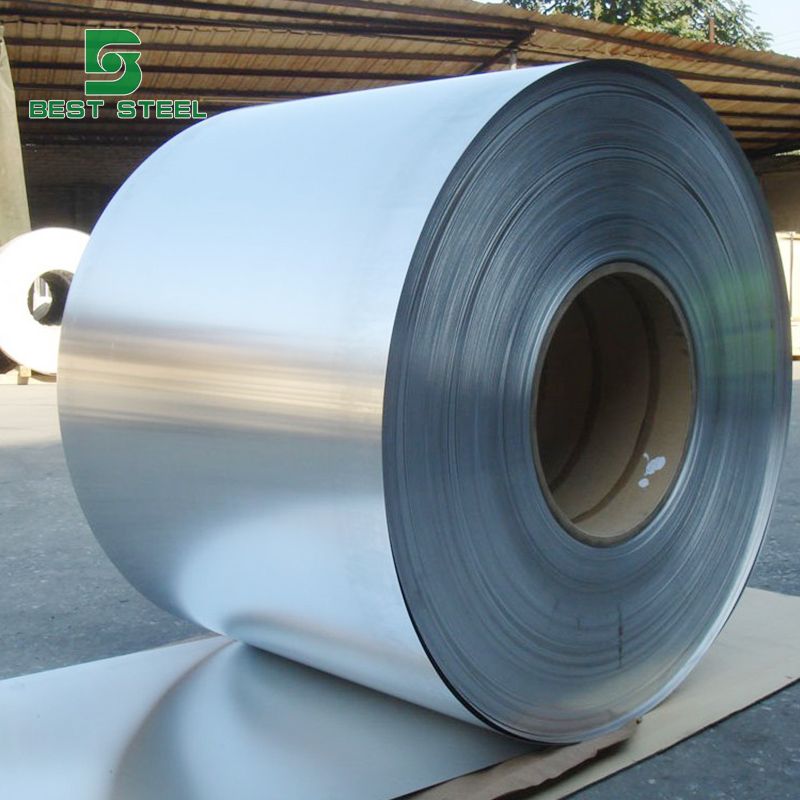

Steel Mesh: Made from welded wire fabric (WWF), steel mesh is a common choice for reinforcing concrete slabs and pavements. The steel bars are arranged in a grid pattern and welded together at the intersections.

Fiberglass Mesh: Lightweight and non-corrosive, fiberglass mesh is often used in areas exposed to moisture and chemicals.

Plastic Mesh: Made from high-density polyethylene (HDPE), plastic mesh is durable and resistant to corrosion and alkalis.

Fiber Reinforced Polymer (FRP) Mesh: Comprising of synthetic fibers, FRP mesh offers high tensile strength and resistance to chemical attacks.

Additional reading:Advantages of Stainless Steel Wire Rope Mesh for Marine Applications

How do I choose a screen mesh?

How do you improvise a grill mesh?

Why Choose 3D Welded Wire Mesh Fencing?

How is Welded Mesh Measured and What are the Dimensions of Welded Mesh?

Benefits and Applications of Epoxy Coated Wire Mesh

Ultimate Guide to Metal Window Mesh: Benefits, Installation Tips, & Maintenance Advice

Benefits of Using Mesh in Concrete

Crack Control: Mesh helps control the width and spread of cracks by holding the concrete together.

Load Distribution: It evenly distributes the load across the concrete, reducing stress concentrations.

Increased Durability: Mesh reinforcement enhances the overall durability of concrete, making it more resistant to environmental factors and mechanical loads.

Improved Flexural Strength: The presence of mesh increases the flexural strength of concrete, allowing it to withstand bending and tension forces better.

Effectiveness of Mesh in Preventing Concrete Cracks

Mechanism of Crack Prevention

Mesh reinforcement works by providing a continuous matrix of tensile strength within the concrete. When stress is applied, the mesh absorbs and distributes the tension, preventing the formation of large cracks. Instead, any cracks that do form are typically smaller and less severe.

Practical Applications

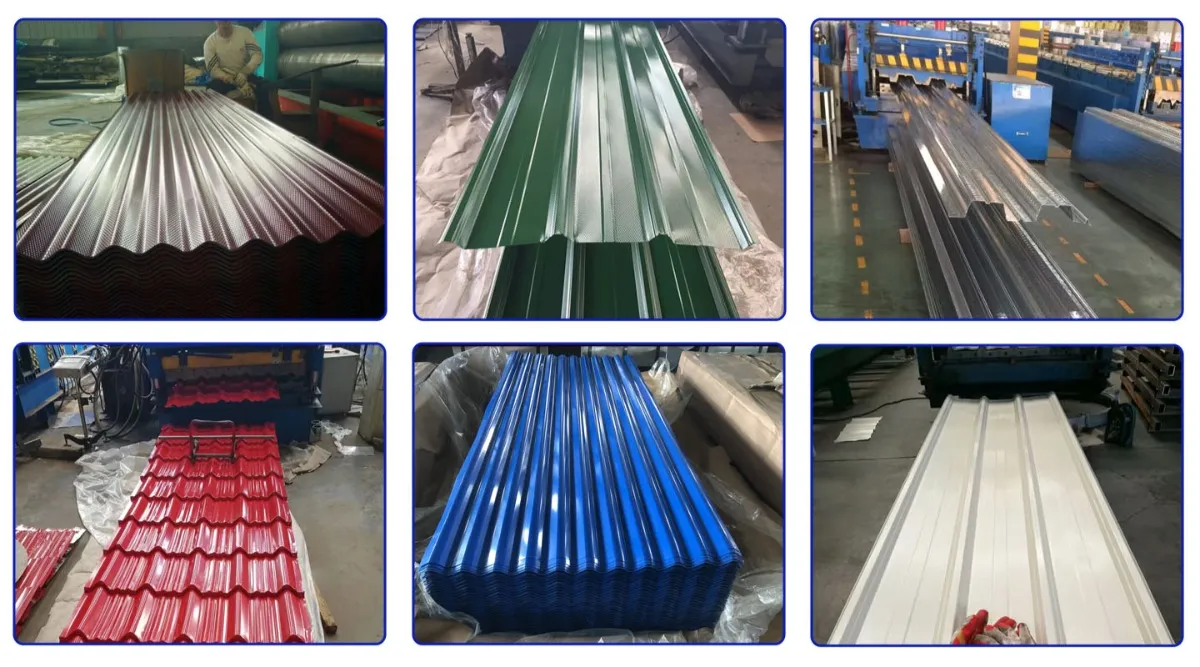

Slabs and Floors: Mesh is commonly used in concrete slabs and floors to prevent cracking due to shrinkage and load stress.

Pavements and Driveways: Reinforced concrete pavements and driveways benefit from mesh as it helps withstand vehicular loads and thermal stresses.

Walls and Panels: In vertical structures like walls and panels, mesh reinforcement helps manage shrinkage and thermal expansion, reducing the risk of cracking.

Precast Concrete Elements: Mesh is used in precast concrete elements to enhance their strength and durability during handling and installation.

Real-World Performance

Studies and field applications have demonstrated that mesh reinforcement significantly improves the performance of concrete structures. For example, in a comparative study of reinforced and non-reinforced concrete slabs, the reinforced slabs showed fewer and smaller cracks over time. Similarly, pavement sections reinforced with steel mesh exhibited better resistance to cracking under heavy traffic loads compared to non-reinforced sections.

Factors Influencing Mesh Effectiveness

Proper Installation

The effectiveness of mesh reinforcement largely depends on proper installation. The mesh must be correctly positioned within the concrete, ensuring it is fully embedded and adequately supported. Poor installation practices, such as inadequate overlap or improper spacing, can reduce the effectiveness of the mesh.

Quality of Materials

The quality of the mesh material also plays a crucial role. High-quality steel or synthetic fibers with appropriate tensile strength and durability are essential for effective reinforcement.

Concrete Mix Design

The concrete mix design, including the water-cement ratio, aggregate size, and admixtures, can influence the overall performance of mesh-reinforced concrete. A well-designed mix will complement the reinforcement, enhancing crack resistance and durability.

Environmental Conditions

Environmental factors, such as temperature, humidity, and exposure to chemicals, can affect the performance of mesh-reinforced concrete. Appropriate measures, such as using corrosion-resistant mesh in aggressive environments, are necessary to maintain effectiveness.

Conclusion

In conclusion, mesh reinforcement is a highly effective method for preventing and controlling cracks in concrete structures. By enhancing the tensile strength and distributing stress more evenly, mesh significantly improves the durability and longevity of concrete. Proper installation, quality materials, and a well-designed concrete mix are essential to maximize the benefits of mesh reinforcement. Whether used in slabs, pavements, walls, or precast elements, mesh plays a crucial role in maintaining the structural integrity of concrete.

What Are Wear Plates Used For?

Hastelloy Clad Plate: The Perfect Fusion of Strength and Corrosion Resistance

Are There Different Types of Aluminum Coils?

What are the difference between ball bearings and roller bearings?

What are the advantages of using galvanized steel coils?

What To Consider When Choosing Business Trash Cans

Sintered Porous Metal Stainless Steel Discs: Versatile and Reliable